Photographs: Babu/Reuters T N Ninan in New Delhi

Take a look at the leading "emerging market" exporters of textiles and clothing. Whether it is China, Bangladesh, Vietnam, Turkey or Indonesia, you will find that their exports of clothing are more than their exports of textiles. India (as also Pakistan) has the reverse situation - textile exports are one-and-a-half times garment exports.

And the imbalance is growing, even as India has lost ground in the global garment rankings. It used to be the second-largest garment exporter (next only to China). But in the last few years, Bangladesh, Vietnam and perhaps Turkey too have either caught up or pulled ahead.

...

Why is India's garment industry stuck in a stagnant loom?

Image: A salesman waits for customers inside a V-Mart retail store in New Delhi.Photographs: Adnan Abidi/Reuters

India's garment exports ($12.4 billion last year) are less than a tenth of China's. Bangladesh, which used to be smaller, is now 60 per cent bigger. So why is it that, despite having an abundance of the principal raw material in the form of cotton, a strong textile tradition, and armies of under-employed people in the countryside needing more productive work, India's garment industry is stuck in a stagnant loom?

The answer can only be deficiencies in policy and infrastructure - starting with the original stupidity of reserving garment production for the small-scale sector. Equally bizarre, India is the world's second largest producer of raw cotton, but in some years exports up to 40 per cent of its production, mostly to China.

...

Why is India's garment industry stuck in a stagnant loom?

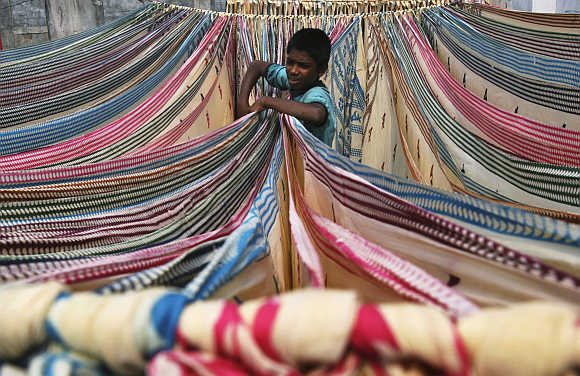

Image: A boy separates starched sarees left to dry on the roof of a cotton factory in Hyderabad.Photographs: Krishnendu Halder/Reuters

Sometimes, these exports cause raw material costs to rise for the domestic industry. This is a repeat of that old story about exporting iron ore to China, which uses it to make steel that India then imports. Even in polyester, where India is a large exporter of intermediates, the yarn or fibre is cheaper elsewhere.

But if India has missed one bus, another is coming along. China has begun to vacate segments of the garment industry on account of rising wage costs, and global buyers are looking for options to Bangladesh in the wake of successive tragedies there, like fires in factories and a building collapse that killed hundreds.

...

Why is India's garment industry stuck in a stagnant loom?

Image: A labourer pulls down a handcart after loading a bundle of processed cotton at a processing unit in Kati town, 50km north Ahmedabad.Photographs: Amit Dave/Reuters

But all too few global buyers are looking at India - which negotiated hard during the Uruguay Round of trade talks to open up the international textile trade, but has benefited relatively little since 2004, when more open trade came into effect.

Labour costs hold one key to understanding the problem. In Karnataka, a unit that observes the minimum wage stipulations pays the equivalent of $110 per month at the starting level; the mandatory minimum wages in and around Delhi would be higher.

In comparison, Bangladesh pays $45 upwards. Many Indian exporters will sidestep the minimum wage stipulations, but the labour market is unlikely to allow much lower payments in the main garment production centres.

...

Why is India's garment industry stuck in a stagnant loom?

Image: An employee inside a textile mill in Ahmedabad.Photographs: Amit Dave/Reuters

In any case, labour is by no means the only factor, since Chinese wages are now up to three times India's (it does, after all, have more than three times India's per capita income). What needs creating is an ecosystem that helps garment exporters flourish.

The point to focus on is that, minuscule as India's garment sector is in relation to its potential, it employs eight million people. Double the industry's size and another eight million jobs will be created.

As it happens, if you take the 2.16 billion man-days of works created under the rural employment guarantee scheme in 2011-12, it works out to about eight million man-years - at half the wages that the garment industry pays.

...

Why is India's garment industry stuck in a stagnant loom?

Image: A woman dries paper cones used by the textile industry to wrap cotton and silk fibres at a factory on the outskirts of Jammu.Photographs: Mukesh Gupta/Reuters

The government spent Rs 38,000 crore (Rs 380 billion) on that programme in one year, but gives little time and attention to an industry that can create the same employment, at double the wages, at very much lower cost. So why are government handouts considered a form of "inclusion" superior to providing people with better-paying jobs in successful industrial establishments?

article